Introduction and background

If you shop watches at all, you'll see different materials used to make the cases. Most common are probably 316L stainless steel, 904L for Rolex and maybe titanium. In the last ten years or so, high-end brands have started introducing better materials such as ceramics and odd-sounding new alloys with Fancy Tradenames!

Ahem. I'm here to help. Let's dive in.

Why coatings and platings and plate are bad

Remember, if you will, the gold-plated cases of the sixties and seventies? Such as the Seiko LordMatic 5606?

or the dings on my IWC 3536 Aquatimer:

The problem is that any plating wears out eventually. Friction, impact damage, corrosion from saltwater and sweat... Sooner or later it'll get leprous, and you can't fix it.

With plain steel (or any homogeneous metal) you can at least polish/sand it, often yourself with patience and simple tools. So I am very cautious of surface-hardened materials, because they are coatings, and sooner or later they will wear.

Austenitic and martensitic

You'll see these two words a lot. They correspond to different crystal structure in the metal. Austenite is body-centered cubic, cannot be heat-treated.

Martensitic is, as wikipedia puts it:

... most commonly refers to a very hard form of steel crystalline structure, but it can also refer to any crystal structure that is formed by displacive transformation.

From my copy of "Materials Science for Engineers":

Martensite: Iron-carbon solid solution phase with acicular, or needlelike, microstructure produced by a diffusion less transformation quenching of austenite.

Think of them as two types of structure, with different tradeoffs. More details on this as I learn it.

316L

Grade 316L (for 'low carbon') is often called 'marine grade' or 'surgical' stainless. Good all-around material, well understood and tough. Good corrosion resistance, easy to scratch, inexpensive. The standard mid-to-high-grade sport watch case material.

Rolex 904L

Rolex uses 904L, which is about the same hardness (HV) as 316L, but has a nicer color and slightly better resistance to acids and elevated temperatures. While their pitch implies 904L is harder, it's not; they use stamping due to their high production volumes. (Source)

Kolsterizing and tegimenting

Two different ways of surface-hardening steel. Kolsterizing is only for austenitic steels (Source) and is seen on brand Corvus and unknown others.

Tegimenting (Source):

Sinn uses tegimented 316 SS to increase scratch resistance. It forms a shell that is 4 - 5 times harder than the underlying SS. The process is called SAT12 and was patented by an Ohio company called Swagelok in August of 1998. In typical case hardening, SS is heated to near it's melting point, but with tegimentation the temperature is kept much lower. This keeps carbides (carbon bonded with other elements - particularly chromium in this case) from forming. Then they carburize (infuse carbon onto) the surface layer to increase the strength of the steel. The finished product can be dented under extreme cases, but resists scratches better than even ice-hardened steel.

Sinn

Sinn was the one where I first considered changing my mind. They call their process 'Tegimenting', which is a very hard coating over 'submarine steel.' Which is actually ThyssenKrupp VDM 1.3964 (Source) Sinn's steel is good, but read the fine print - many of their watches only have the tegimenting on the bezel, not the entire watch. You may not have what you thought.

Damasko

Damasko actually made the cases for Sinn until 2002, and as WatchTime noted, Damasko is an expert case maker. Damasko's approach is a bit different than Sinn, in that they use steel (Cronidur 30, source) that is ice-hardened and thus tough all the way through:

First the metal is heated to above 1000C, then rapidly quenched to room temperature in oil. This is followed by deep freezing at -80 C for 1 hr, then tempering for several hours at 160C to give hardness >710 HV.

(Source)

According to Damasko this leads to higher corrosion resistance too, a PRE of 50-52.

IWC titanium

My now-sold IWC 3536 Aquatimer had surface-hardened titanium, which despite its 2400HV rating (Source) had plenty of nicks and dings. I tend to agree with Damasko, when they attribute this to 'the eggshell problem,' where a hard coating over a soft metal can fail more easily than you'd think.

Bremont

Bremont uses kolsterizing and then a plasma coat (DLC) with a Poeton Apticote 800/24 to apply a tungsten carbide + cobalt coating. (Source) The result is a very high 2000HV rating. Also used on turbine blades and similar aerospace applications, so I would guess it to be durable; the brand is too new and the watches too young to have an informed opinion yet.

Graphical comparison

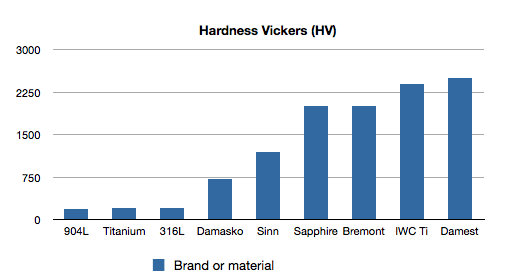

I dropped the numbers into a spreadsheet, using the centers of any given as ranges:

I've also included Damasko's 'Damest' (Source) as well, which is the PVD process they use on the bezel, and plain sapphire for comparison.

Discussion

Obviously, the Damast and IWC look great, but as seen above HV doesn't tell the whole story. Tougher steel is a good idea but it's not magic.

Pitting resistance equivalent, or PRE

PRE is a simple formula (Source):

PRE = %Cr (Chromium) + 3.3 x %Mo (Molybdenum) + 30 x %N (Nitrogen)

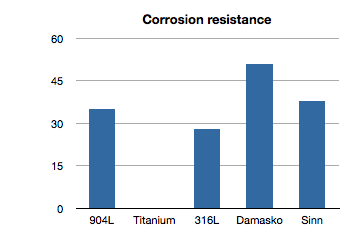

Any experienced watchmaker can tell you that Rolexes corrode at the same rate as normal stainless, so let's look at that a bit. The figure of merit is PRE, and here are some numbers, again with ranges plotted as the average:

Since titanium (Grade 5 probably, which is actually an alloy) has other components, PRE doesn't apply. From what I've read, it's quite non-corrosive, and is used for demanding oceanic applications such as depth sondes, AUVs and the like.

In general, always rinse any steel after use in saltwater, and remember that sweat corrodes too.

Discussion and conclusions

It's not a simple tradeoff, but so far I think the Damasko approach is best for a long-term watch. The Sinns are nice, but only toughening part of the watch is lame and the prices are higher than Damasko. The eggshell IWC was a lose, full stop. The Damasko steel is susceptible to magnetization, so they need to have an antimagnetic shield to achieve their 1,000 Gauss (0.1Tesla) rating. The new A35 movement forgoes the shield, so from that I conclude that the silicon hairspring and balance solved the magnetism problem.

Ceramics and liquidmetal and such, those are another post!